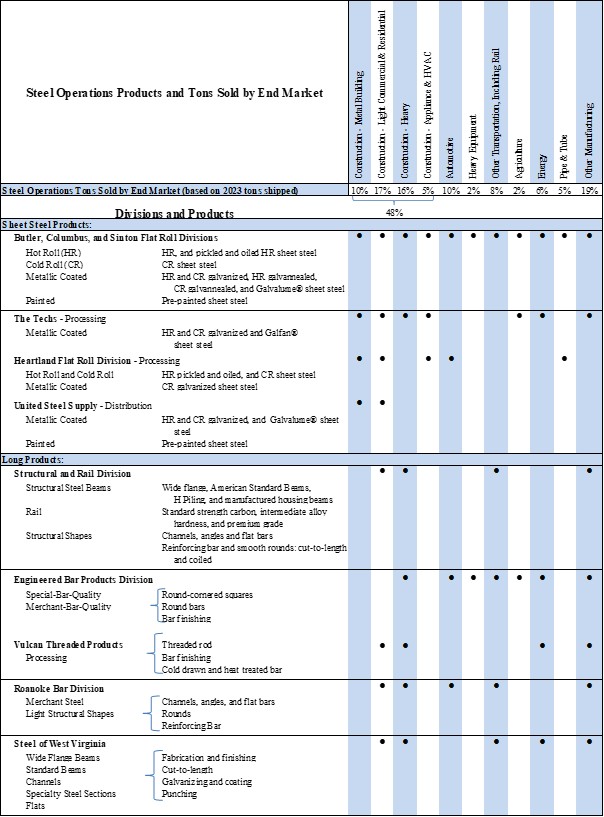

The steel manufacturing business is cyclical in nature, and the selling price of the steel we make may fluctuate significantly due to many factors beyond our control. Furthermore, a number of our products are commodities, subject to their own cyclical fluctuations in supply and demand in both metal consuming and metal generating industries, including the construction and manufacturing industries. The timing, magnitude and duration of these cycles and the resulting price fluctuations are difficult to predict. The sale of our manufactured steel products is directly affected by demand for our products in other cyclical industries, such as construction, automotive, manufacturing, transportation, heavy and agriculture equipment, energy and pipe and tube (including OCTG) markets. Economic difficulties, stagnant or slow global economies, supply and demand imbalances, supply chain disruptions, periods of heightened inflation or high interest rates, and currency fluctuations in the United States or globally may decrease the demand for our products or increase the amount of imports of steel into the United States, which may decrease our sales, margins and profitability.

Volatility and major fluctuations in prices and availability of scrap metal, scrap substitutes and supplies, and our potential inability to pass higher costs on to our customers, may constrain operating levels and reduce profit margins.

Steel producers require large amounts of raw materials, including ferrous scrap metal and scrap substitute products such as pig iron and pelletized iron, and other supplies such as zinc, graphite electrodes and ferroalloys. The principal raw material of our EAF steel operations is recycled ferrous scrap derived from, among other sources, “home scrap,” generated internally at steel mills themselves, industrial scrap, generated as a by-product of manufacturing, obsolete scrap, recycled from end-of-life automobiles, appliances and machinery, and demolition scrap, recycled from obsolete structures, containers and machines. The prices for scrap are subject to market forces largely beyond our control, including demand by United States and foreign steel producers, freight costs and speculation. The scrap metal recycling industry has historically been, and is expected to remain, highly cyclical and the prices for scrap have varied significantly in the past, may vary significantly in the future and do not necessarily fluctuate in tandem with the price of steel. Moreover, some of our integrated steel producer competitors are not as dependent as we are on ferrous scrap as a part of their raw material melt mix, which, during periods of high scrap costs relative to the cost of blast furnace iron used by the integrated producers, give them a raw material cost advantage over EAF mills. However, given environmental considerations of investors, customers and regulators, additional EAF mills may be constructed, or companies currently operating blast furnace mills may invest in EAF mills, leading to increased demand in ferrous scrap possibly resulting in higher scrap prices. While our vertical integration into the metals recycling business and our liquid pig-iron operations are expected to enable us to continue being a cost-effective supplier to our own steelmaking operations, for some of our metallics requirements, we still rely on other metallics and raw material suppliers, as well as upon general industry supply conditions for the balance of our needs.

The availability and prices of raw materials and supplies, particularly those with positive environmental attributes, may also be negatively affected by new, existing or changing laws, regulations, sanctions or embargoes, including those that may impose output limitations or higher costs associated with climate change or GHG allocation by suppliers, interruptions in production, accidents or natural disasters, changes in exchange rates, global price fluctuations, the availability and cost of transportation, and competing uses, all of which may be heighted during times of war or hostilities. As a major producer of galvanized steel products, we purchase and consume a large amount of zinc, which if purchased at high prices, may adversely affect our profit margins. Any inability to secure a consistent, cost-effective and timely supply of our raw materials and supplies may adversely affect our business, financial condition, results of operations and cash flows.

Additionally, our inability to pass on all or a substantial part of any cost increases, whether due to positive environmental attributes, inflation, supply and demand imbalances, or otherwise, or to provide for our customers’ needs because of the potential unavailability of raw materials, supplies or required environmental attributes, may result in production slowdowns or curtailments or may otherwise adversely affect our business, financial condition, results of operations and cash flows.

The cost and availability of electricity, natural gas, oil and other energy resources are subject to volatile market conditions.

We consume large amounts of energy to melt scrap, reheat semi-finished products for rolling into finished products and perform other steps necessary to our production process. We rely on third parties for the supply of energy resources